Project AVOID Part 4; Holes

With a working AVOID (Attenuating Vehicular Obstacle Interference Design) rock and tilt sensor we had one last sensor type to design. This sensor needed to be capable of detecting holes, pits or chasms in front of the rover and alerting the rover in time to prevent it from falling in. The first solution we designed was simple; a pole mounted to the front of the rover, with a wheel attached to one end. As the rover drove this wheel would roll along the ground in front of the rover. Then, if the rover were to come across a chasm this wheel would drop slightly into the hole. The force of this fall would then trigger the pin and alert the rover of the hazard.

This seemed like a plausible solution, but as always, we needed to test it. The objectives of this first test were to confirm the sensor’s function and verify that the wheel would not become trapped after falling into a hole. We fabricated a prototype of this sensor and mounted it to the GTS (Ground Test System) to perform this test.

During the test, the sensor failed catastrophically, becoming detached from the GTS. Investigation revealed that the sensor had not been properly secured. This issue was quickly resolved and after reattaching the sensor we performed another test.

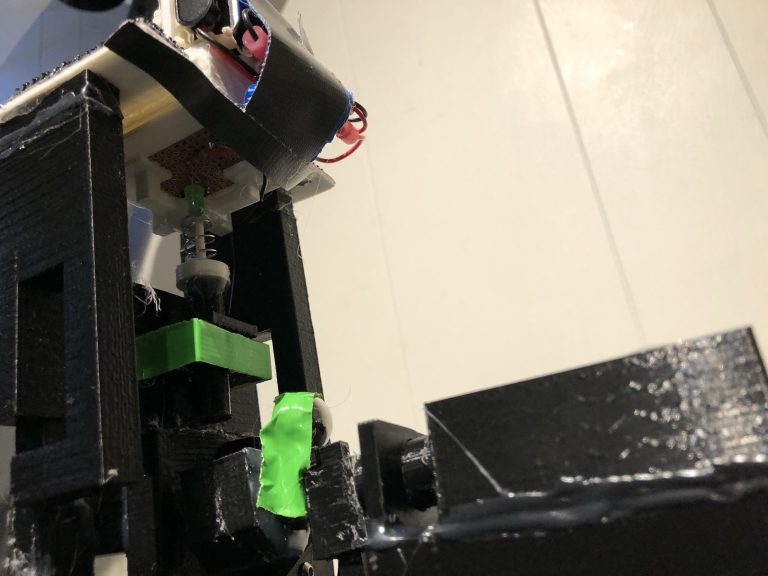

This second test was successful and validated the hole sensor design. We then made a few modifications to the sensor in preparation for a final test. The objective of this test was to confirm that the hole sensor would be capable of depressing the pin. Just as the test was about to start, a new problem surfaced. The pole, which is a major component of the hole sensor tended to rotate when the GTS moved. This caused it to become misaligned with the pin and prevent it’s depression. The obvious solution was to design and 3D print supports to reduce this motion, but the submission deadline was only a day away. With so little time available, 3D printing was not an option, as it would take hours for the needed parts to be completed. Instead we used a mix of tape, cardboard, glue and even a pair of pencils to create the supports.

These supports proved sufficient to prevent the rotation, solving this problem. The success of this test marked both the completion of the AVOID hole sensor was well as the entire AVOID project. With all three sensors completed we submitted our entry into the NASA Exploring Hell challenge.

On July 6, 2020 NASA announced the winners of the Exploring Hell challenge that Project AVOID had been submitted to. While we had not been selected as a winner, the experience of competing in the challenge provided many opportunities to explore new areas of design and increase our skills.