This page consists of an overview of the many systems that make up Project Redirect, ranging from test payloads to parachutes. Also included are images and videos related to these systems.

A note on terminology; Often a single system will have several different versions. To aid in differentiation between these versions they are separated into different numbered generations, or gens. A higher gen number signifies a newer system. This gen number is often added to the end of a system’s acronym (ex. GTP-2).

Parachute Systems

Spring Deployed

Our first and most developed type of parachute launcher, the spring powered parachute system used the force of a spring to launch the parachute. Later models were built with twin parachute tubes, so that two main parachutes could be used, a design that theoretically increased reliability but would have likely increased the risk of tangles.

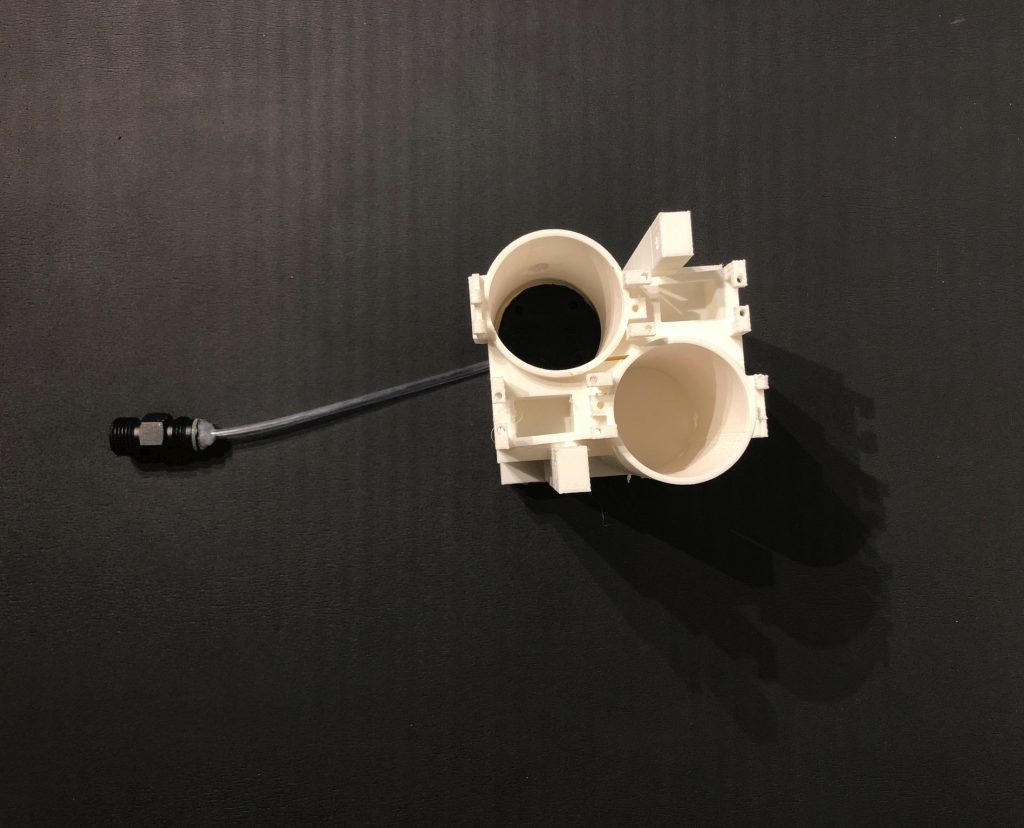

CO2 Deployed

The CO2 powered parachute systems were built to replace the spring powered designs, with the hope that using high pressure gas would prove more successful. Like the proceeding models, twin main parachutes were included.

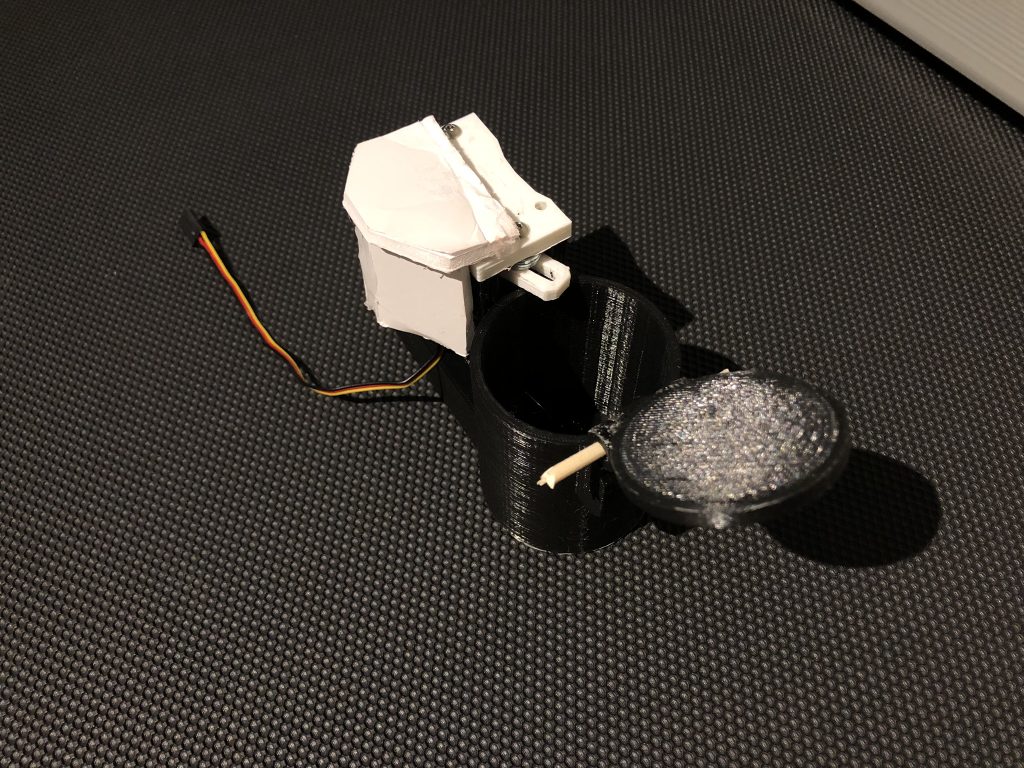

Pilot Parachute Deployed

The latest and only successful system, this type of system uses a small spring launched pilot parachute to pull out and deploy the larger main parachute. In an attempt to reduce complexity and the risk of tangling, the twin main parachutes of the other models was replaced with a single, larger main.

Computer Systems

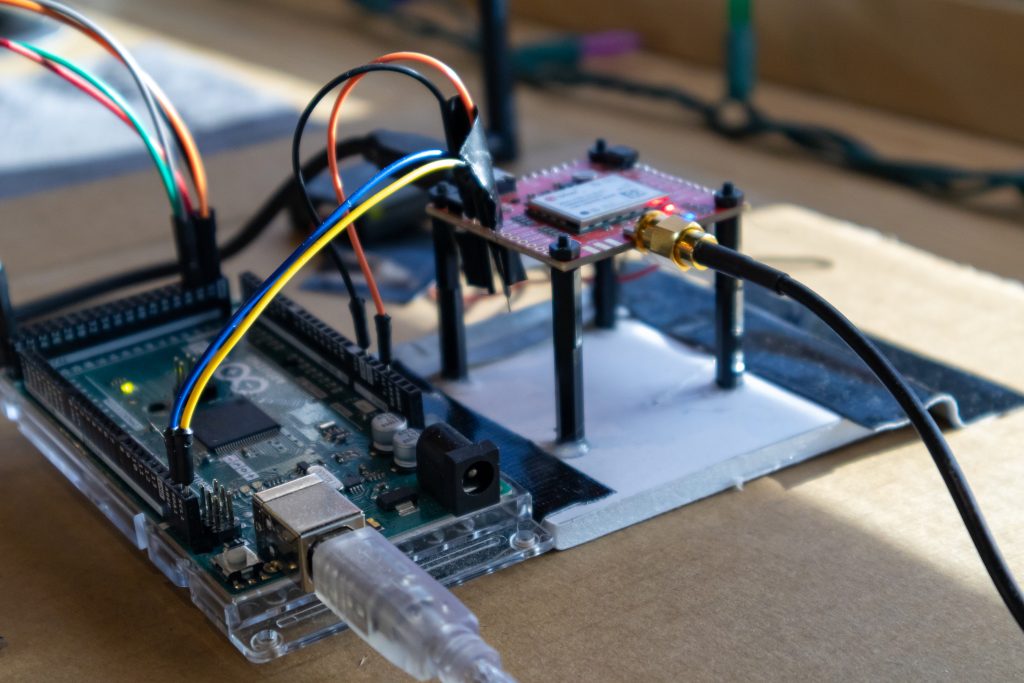

Parachute System Control Computer (PSCC)

Parachute System Control Computers (PSCC) are compact flight computers that are designed to record data during test flights as well as automatically deploy a payload’s parachute at a preset altitude.

Flight Vehicles

Flight Test System (FTS)

The FTS is designed to test various components of Project Redirect in a real world environment by lifting them to a altitude of up to 121 m (400 ft). The FTS is capable of lifting up to 6.6 kg (14.6lbs) allowing it to carry and drop a wide variety of test payloads. The FTS is also equipped with a camera to record the performance of the tests.

“Skipper” Guidance Test Vehicle (GTV)

The Skipper GTV is used as a platform for guidance system development. To fulfill this task it is designed to be easily modifiable to support different hardware and software configurations.

Parachute Test Payloads (PTP)

The parachute test payloads were built to test the newly designed parachute system, without risking a more complex and expansive payload. To achieve this goal, they prioritized a simple and low cost design that reduced the loss in the event of a failure. With the development of the parachute system completed, these payloads are now being used to test the parachute system control computer.

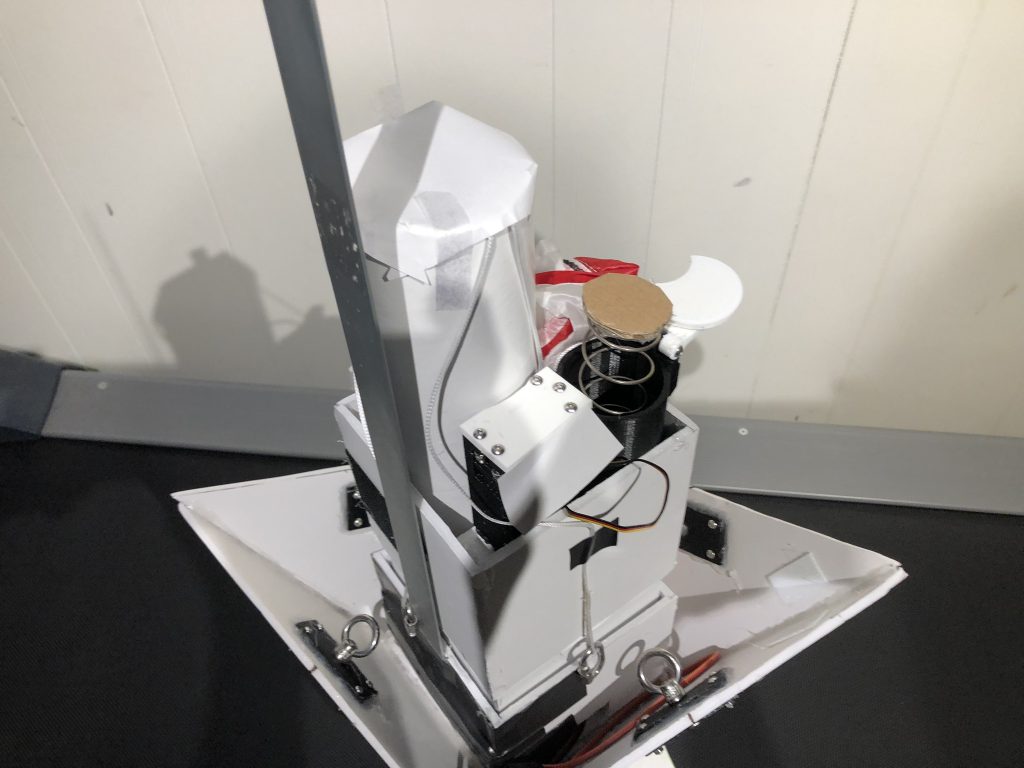

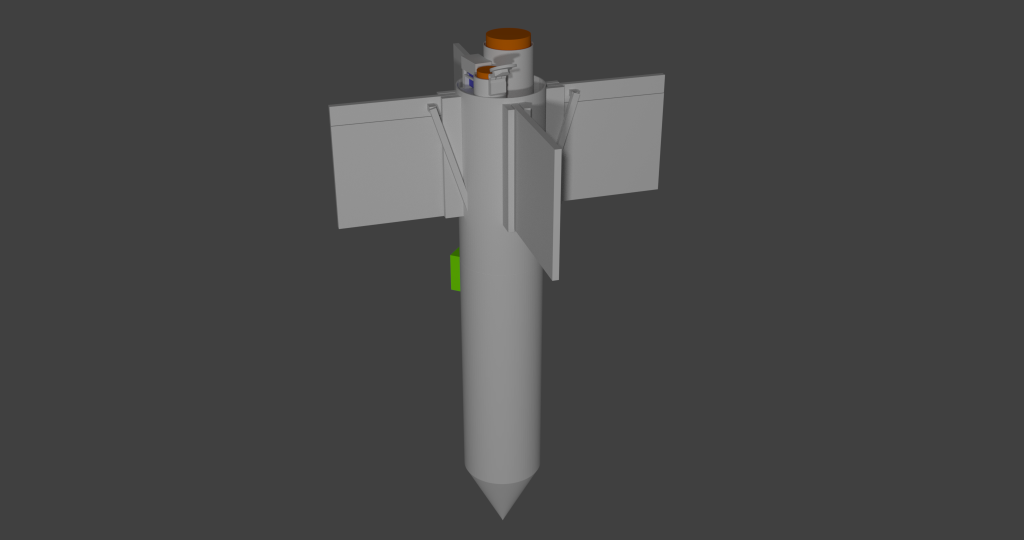

Guidance Test Payloads (GTP)

Guidance Test Payloads (GTPs) are used to test the components of the guidance system in flight, and are thus much bigger and more advanced then the PTPs.