Assembly

After our successes last week, we were confident that we would be ready to fly on Monday. But we had a few final tasks we had to complete before we could fly.

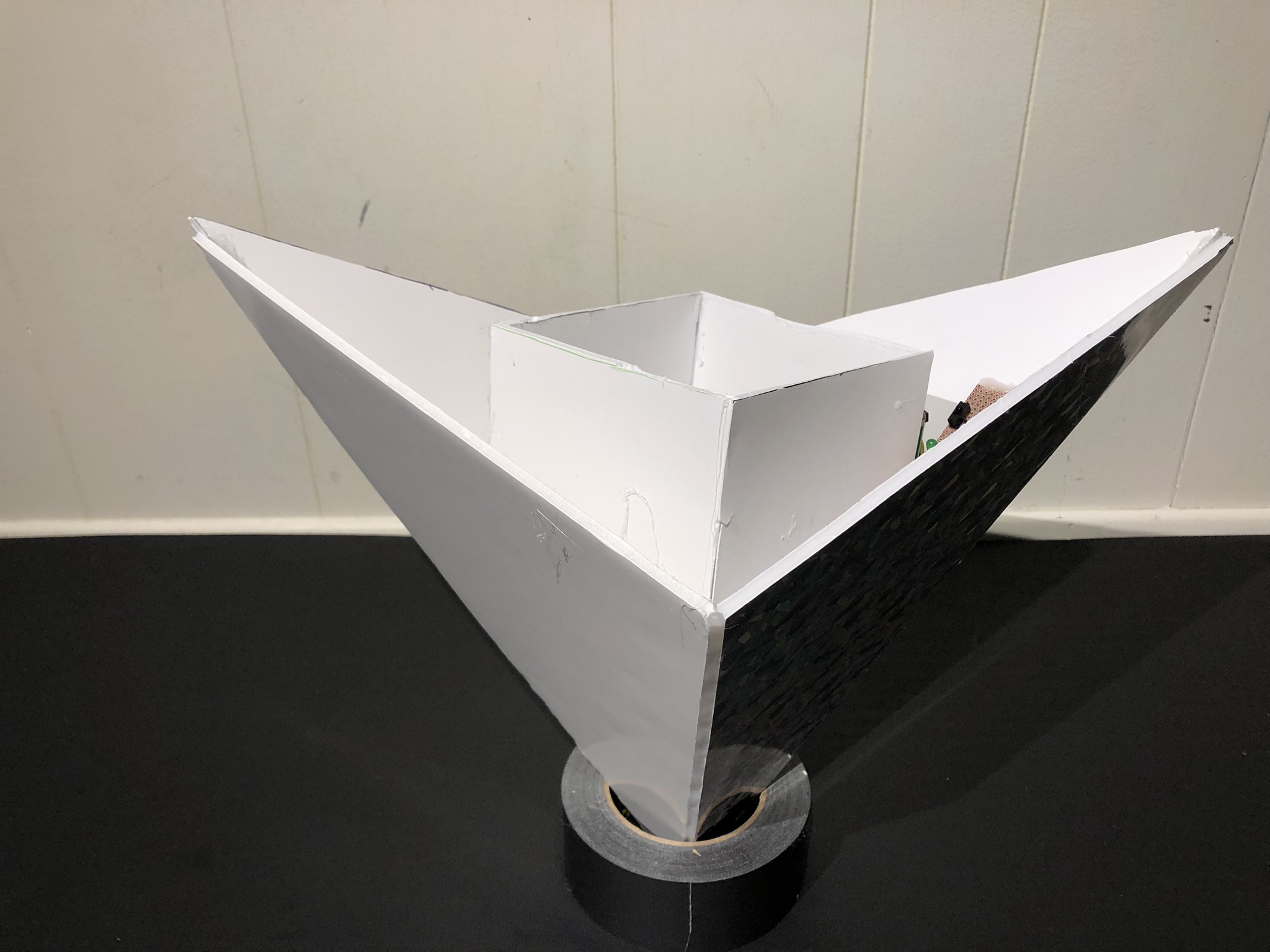

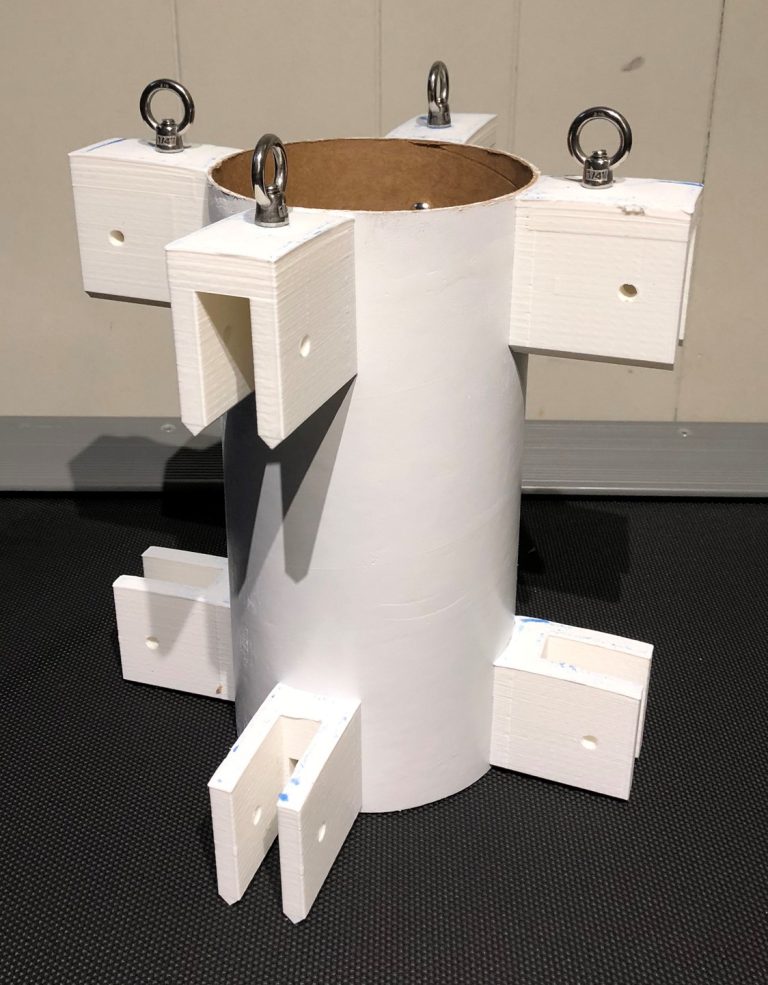

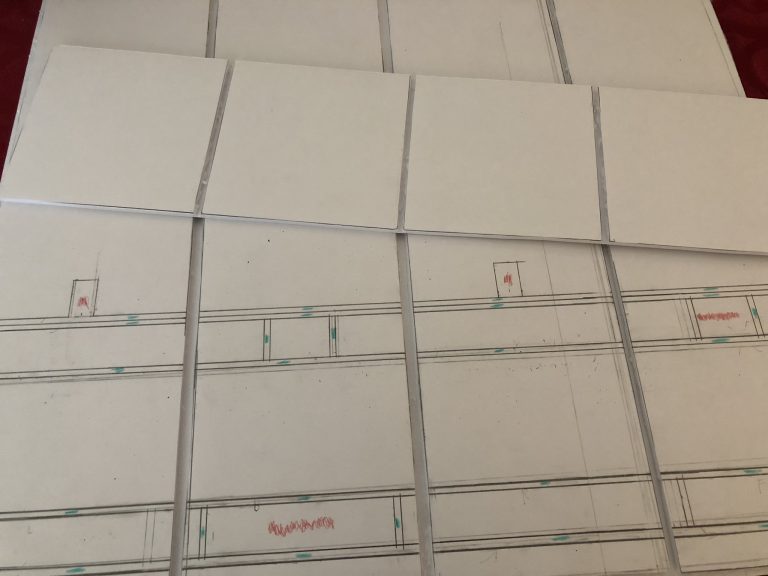

The outer shell of the parachute test payload needed to be completed. This is the payload that we will drop from the FTS (Flight Test System) to evaluate the performance of the parachutes. We assembled the shell, installed the primary and secondary batteries, a receiver and a camera to record the parachutes deployment.

Although this payload is smaller than the guidance test payload that will be used in future tests, it is made of the same materials and constructed in much the same way.

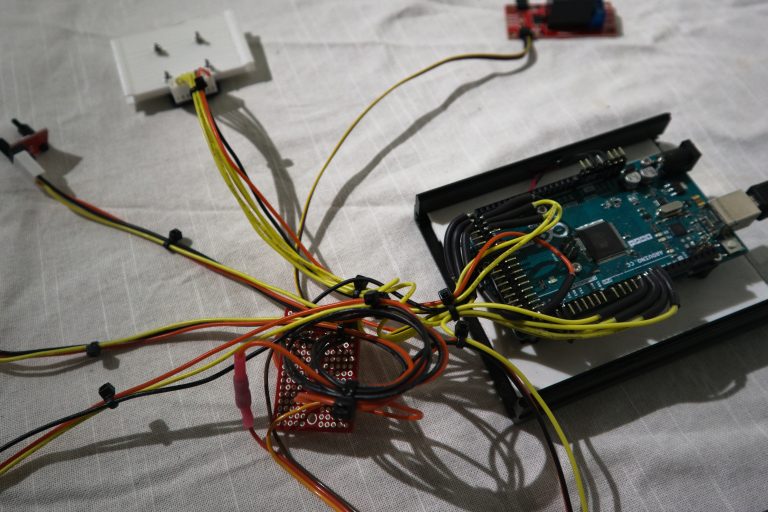

While the test payload was taking shape, we were also working on the parachute system itself. While we have performed many single tube tests we have not fired both tubes at the same time. This was something we needed to test before our flight.

A problem we thought we had fixed weeks ago suddenly resurfaced. The release mechanism arms did not retract fully and prevented the parachutes from deploying. We tried a few modifications to fix the problem. For one, we added more lubricant and then we tried a small ball instead of the standard spacer. None of these fixed the issue and we were forced to cancel our test flight

At this point, we are exploring the option of continuing to work on the spring powered system or if we want to redesign the parachute system in full.